Higher uniformity and throughput can be achieved with high performance Delta Cathodes and high throughput option. * Typical results with Standard Delta Cathodes. * Assumes 10 minute pumping, wafer exchange and venting cycle, some processes require pre-heating, extending the loading cycle by as much as 5 minutes.ĭelta Cathode Systems Performance Specifications(Typical) PERFORMANCE FOR TYPICAL METALLIZATION PROCESS-100mm WAFERS

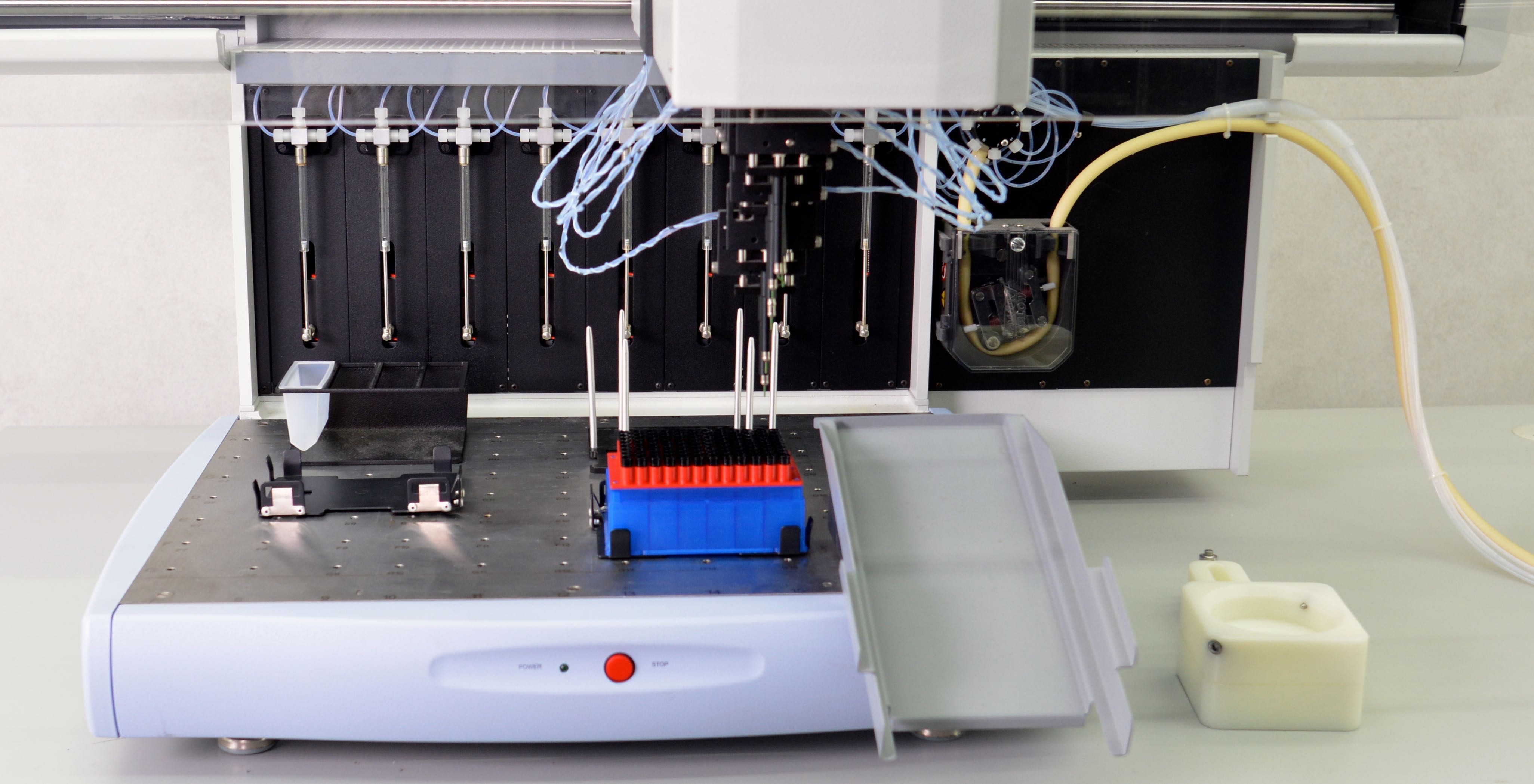

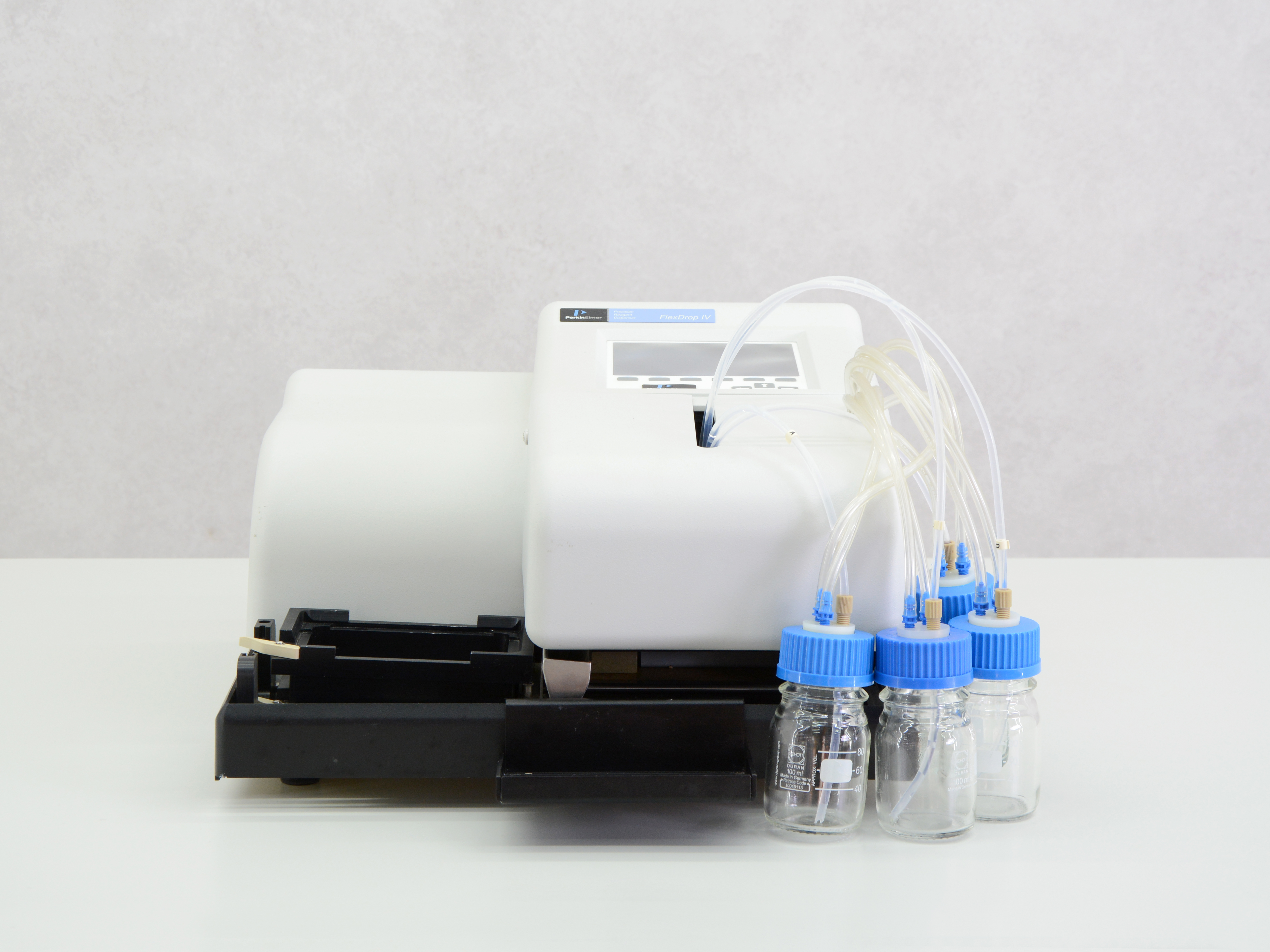

The Delta Cathode Dual Deposition Sputter Module, operable in either a dual DC mode or DC and RF mode, is designed for higher throughput and larger scale production. The Delta Cathode Dual Deposit Sputter Module This wide brand of uniformity means that 5 1/ 4“, 8″, or 14” recording discs can be accommodated in the system. A uniformity of +/-7% is achieved across a 7 3/ 4 inch band suitable for mounting two concentric rows of 100mm wafers. The region of high uniformity is extended across the total 8″ annular width of the pallet. The HIGH THROUGHPUT option consists of a modified shaping aperture, a high performance Delta cathode and a pallet nested for twenty two 100mm wafers. A maximum of twenty two 100mm wafers can be loaded yielding 50% more throughput for a typical metallization process. Provide more uniform deposition over a wider annular region of the pallet. Heating the substrate in this manner and re-sputtering the deposited material through RF bias improves coverage of vertical surfaces in VLSI structures. The high rate sputtering made possible with Perkin Elmer Delta DC magnetron cathodes produces sufficient heat to maintain film temperature in the ideal range. As metallization films become thicker and specularity degrades, further reduction of unwanted gases can be achieved through the use of supplemental hydrogen getter pumping in the Model 4410 and other Delta cathode systems. Optional load lock pumping and wafer degassing further minimize water vapor and hydrogen, the principal contaminants that contribute to hillock growth and poor specularity. High quality aluminum alloy films of 70-90% relative reflectance are routinely produced in high rate DC Delta magnetron systems, yielding wafers easily accommodated in today’s projection mask aligners. With total system background pressure of 5X10 -7 Torr and an instantaneous deposition rate in excess of 8500 angstroms/minute, near-bulk resistivity for aluminum alloy films can be achieved.īy keeping oxygen content below, film hardness for typical 1 micron thick aluminum silicon films can be kept below 100 kg/mm 2 after annealing at 500 oC, minimizing bonding failures. Perkin Elmer sputtering systems ensure low film resistivity by minimizing partial pressure of oxygen and nitrogen below 1X10 -7 Torr. Standard wafer size of 3 inch, 100mm, 125mm and 150mm can easily be accommodated. The Model 4410 and other delta cathode systems can easily handle substrate size up to 8 inches in diameter. Standard Delta cathodes process 50-60 100mm wafers per hour while optional high performance Delta cathodes yield throughput in excess of 80 100mm wafers per hour.Ī particular advantage of a circular batch sputtering system is its adaptability to different substrate sizes. Optional high performance Delta cathodes yield a uniformity of +/-5% over a 7 3/ 4 inch band, allowing processing of up to 22 100mm wafers per cycle.

The substrate pallet can be in excess of 200 angstroms/kw minute with sputtered material utilization approaching.ĭelta cathode systems maximize uniformity of deposition, exhibiting a +/-7% uniformity over a 6″ annular width. The Perkin Elmer Delta cathode systems 4410, are ideally suited to aluminum alloy deposition for gate contact and interconnect metalization.Ī Delta cathode system achieves an instantaneous deposition rate for aluminum alloys of 12,000 angstroms/minute. Power options are available up to 3 kw RF and 10 KW DC. The 4410 is also adaptable to the deposition of dielectrics and employs up to three delta-shaped cathodes in DC magnetron, RF magnetron, or RF diode configuration. Perkin-Elmer 4410 is a delta target sputtering system designed for high rate deposition of metals and metal alloys. The Delta Cathode Systems Perkin-Elmer 4410 You are here: Home > Equipment > Perkin-Elmer 4410 Perkin-Elmer 4410

0 kommentar(er)

0 kommentar(er)